Pharmaceutical industry

Ultimate systems for pharmaceuticals and micropollutants

The global use of pharmaceuticals has been growing steadly for the past decades and the overall spending is predicted to continue grow in the coming years. This rise is driven by a range of factors including the ever growing globlal competition offset by expiration of patents and the rise of generics, new product intakes to mention a few. All of this has resulted in increasing concentrations of pharmaceutical residues in our wastewater streams. This presents a huge struggle for wastewater management around the world to address the potential impacts of these pharmaceutical residues on drinking water quality, the ecosystem and the health of humans and other living organisms.

Current treatment technologies used in wastewater treatment plants are usually not fit to remove microbial stable chemical pollutants and the evaluation of the removal efficiency applied today, is not complete. Pharmaceutical residues and other emerging substances pass through modern wastewater treatment plants and end up in the receiving waters and sludge.

Substances such as antibiotics (e.g. Amoxicillin and Ciprofloxacin), beta blockers and drugs like morphine and codeine are difficult and often impossible to treat in wastewater treatment plants due to their complex chemical structures. Such substances have an adverse effect on fish, plants and whole ecosystems and accumulate over time due to their non-biodegradable characteristics.

Mellifiq offer more than 20 years of experience implementing advanced oxidation solutions and technologies in water treatment for a wide range of industies and municipalites and governmental organisations. Our innovative solutions, combining ozone and conventional technologies, are ideal for water and air treatment in the production process as well as treatment of the discharged wastewater.

Our goal is to offer a more efficient and sustainable solution that helps you improve your business profitability and output quality. By reducing your energy costs you will also automaticaly lower your production facilitie’s environmental impact.

A health risk that can be eliminated

Can pharmaceutical residues be removed effectively and sustainable?

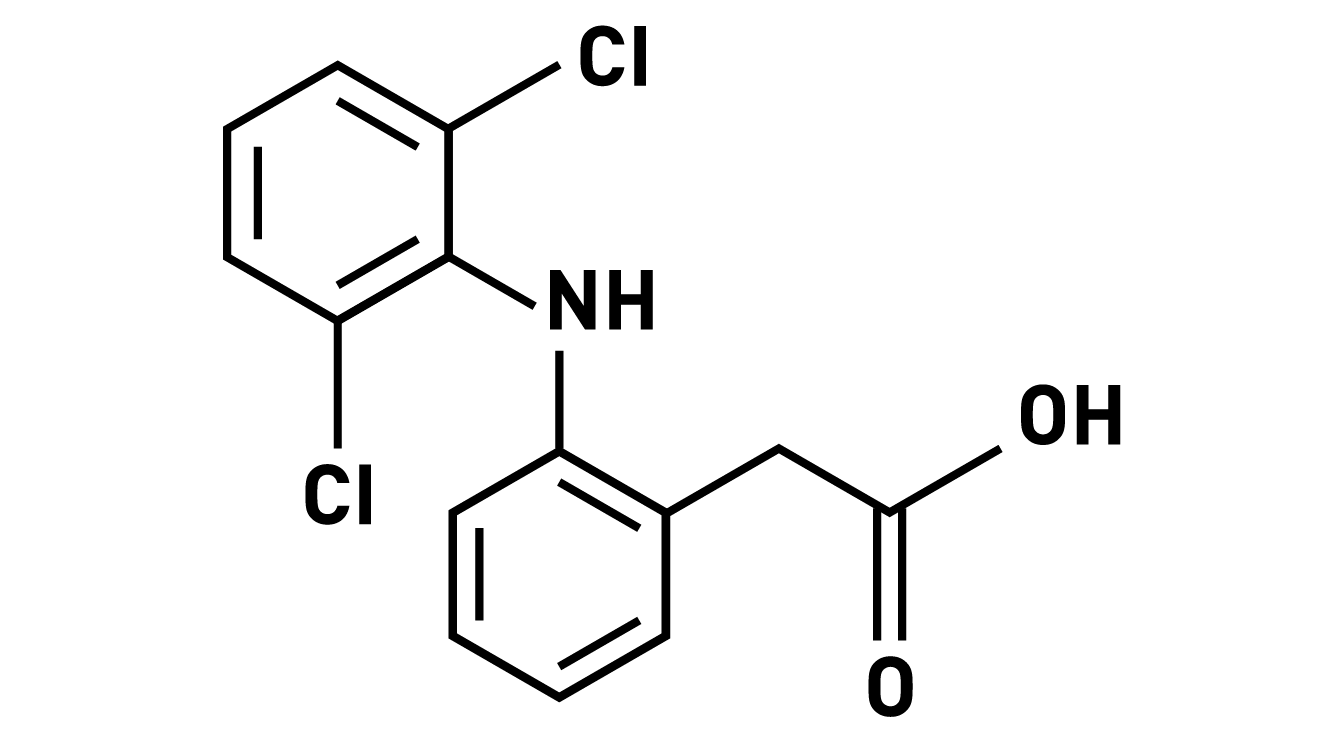

Diclofenac.

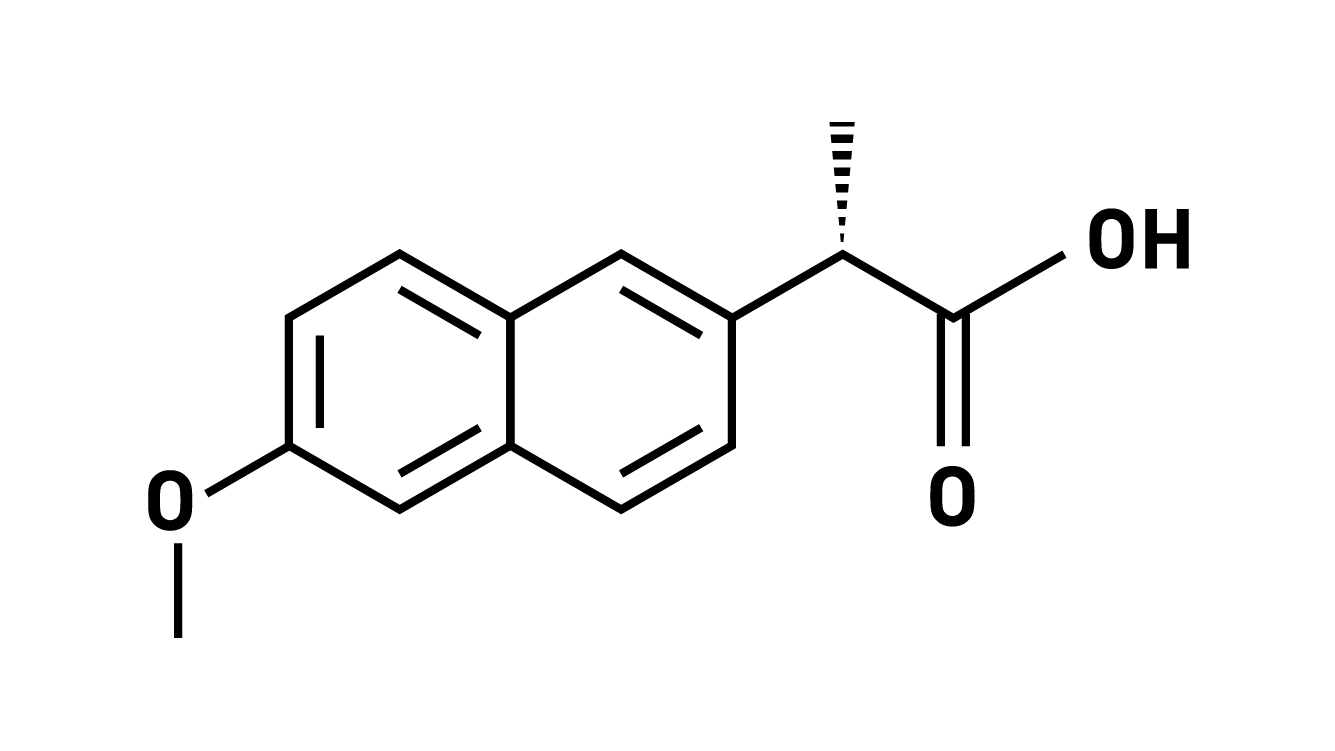

Naproxen.

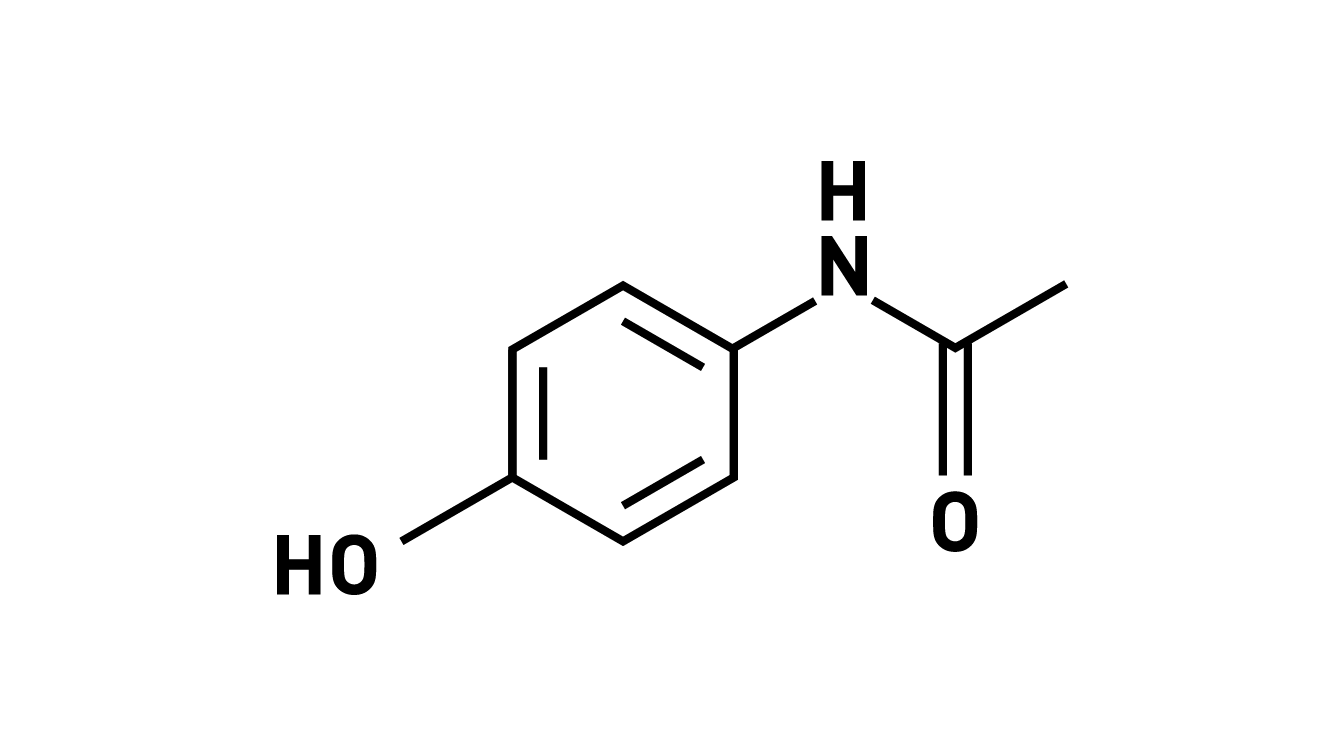

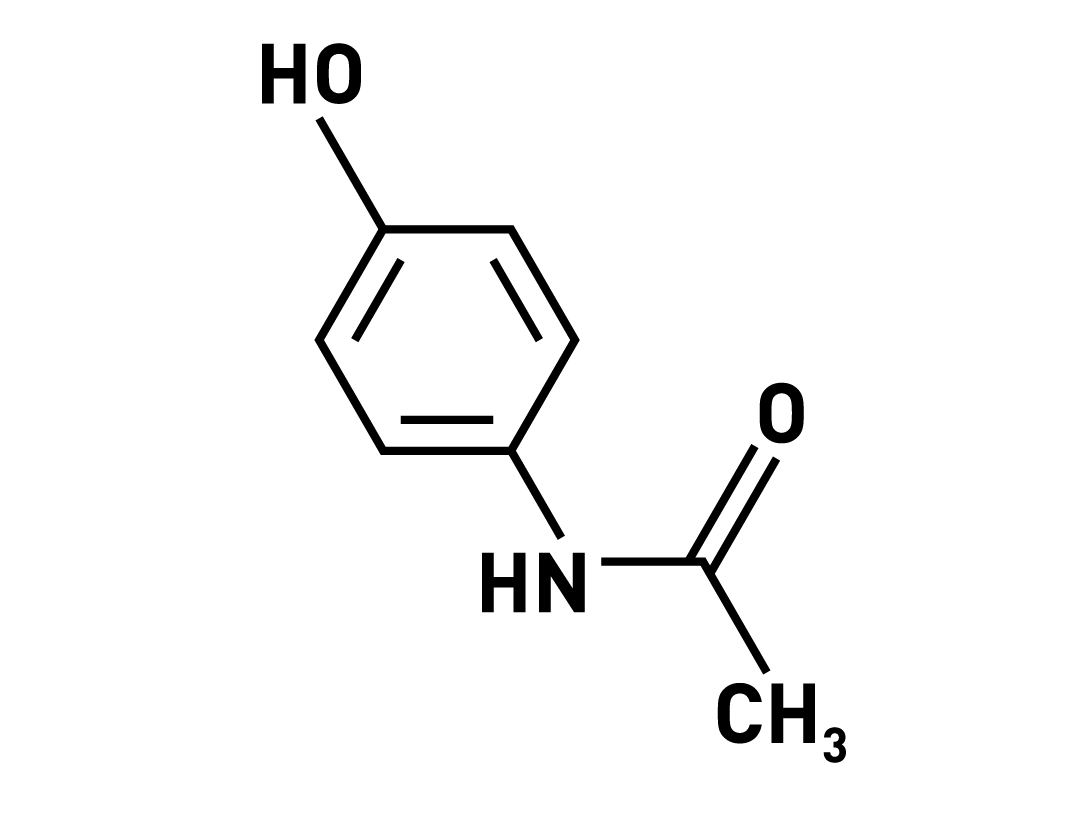

Acetaminophen.

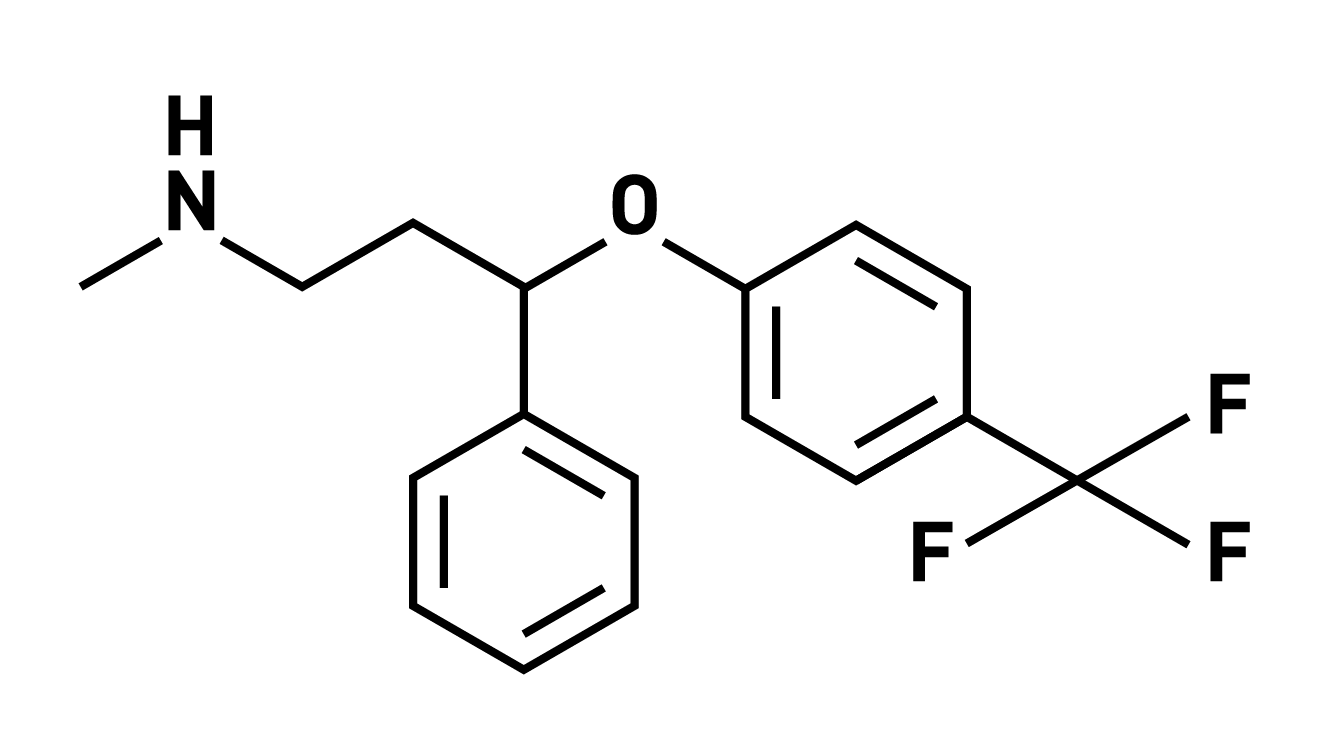

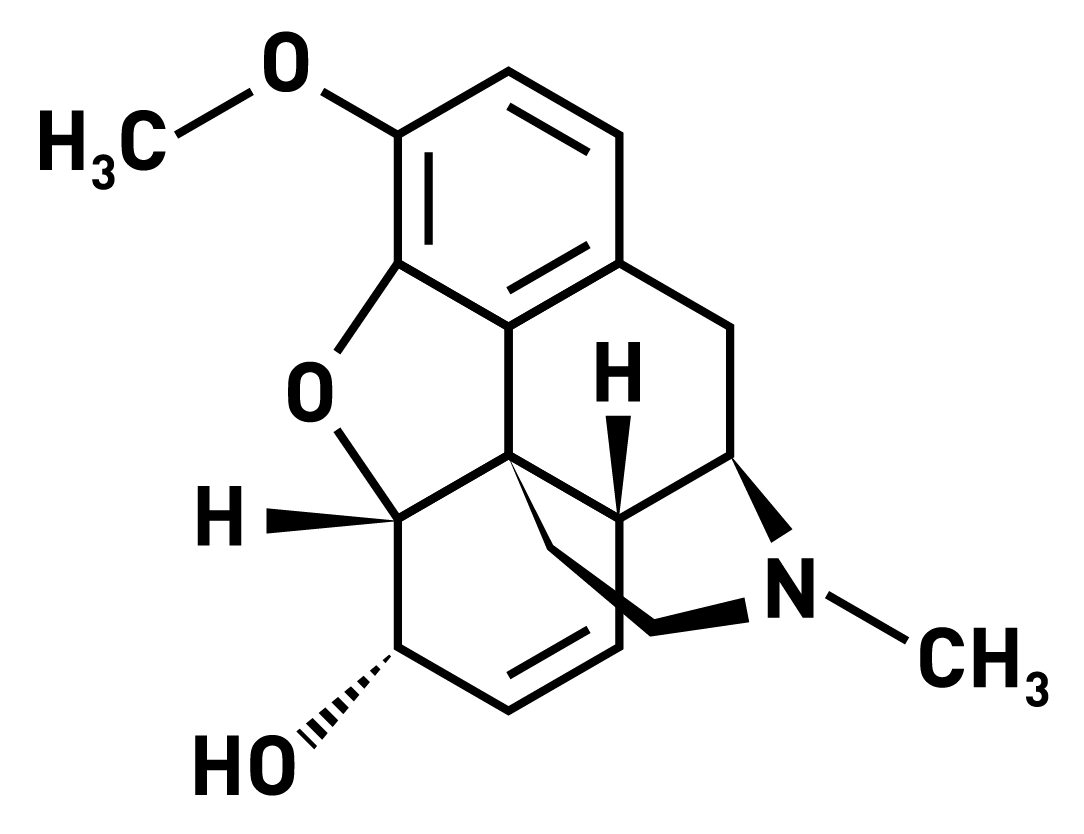

Prozac.

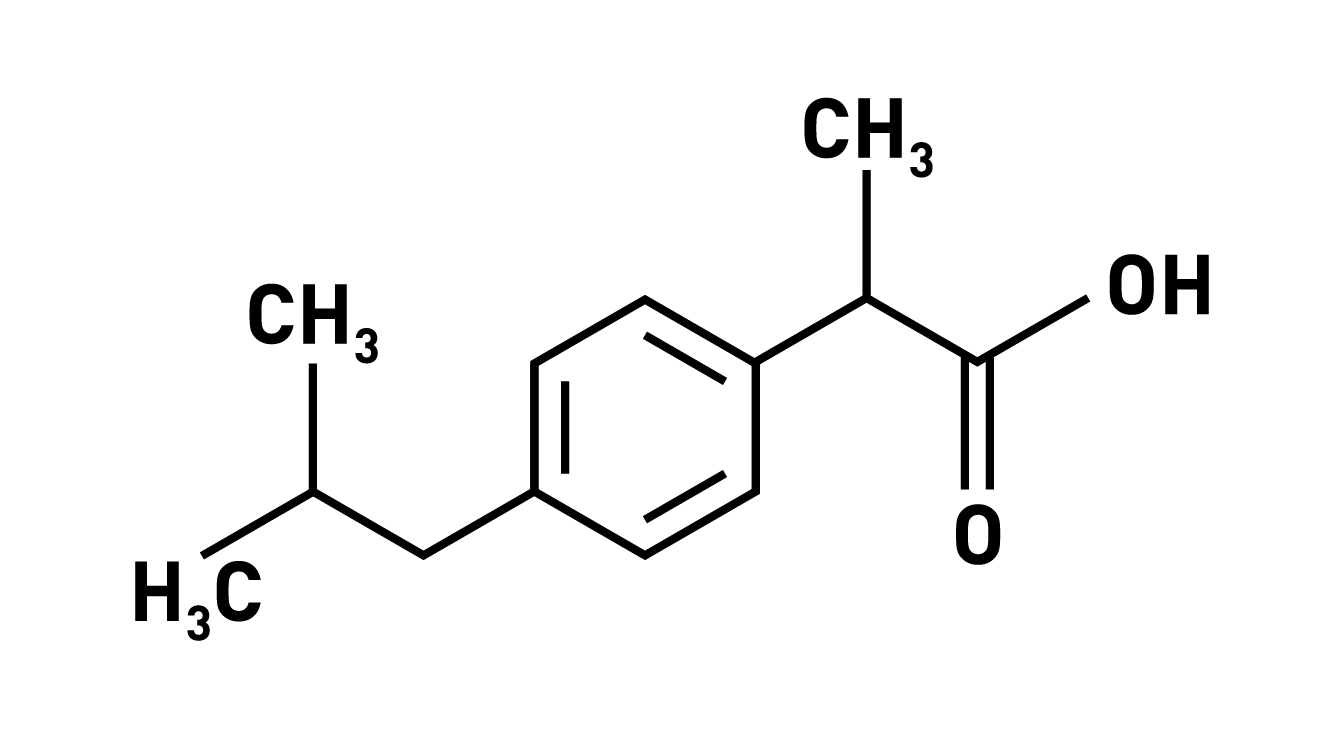

Ibuprofen.

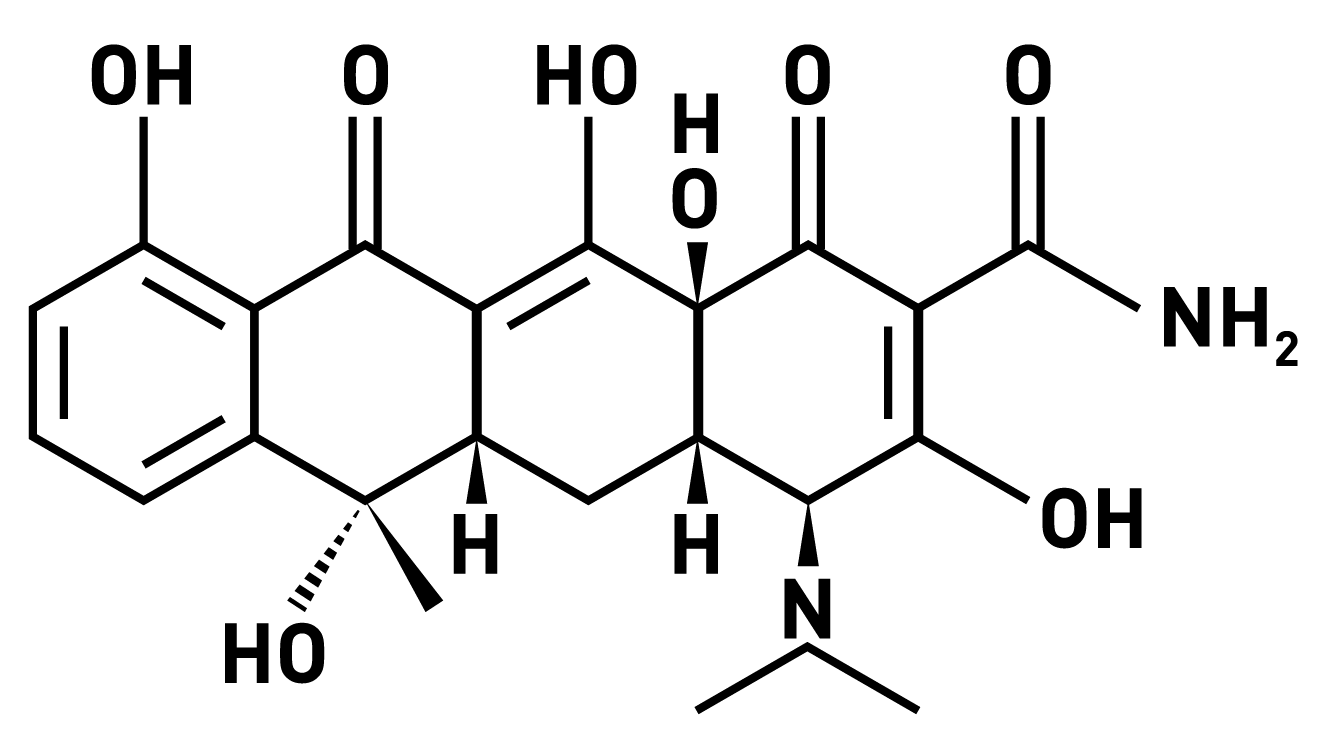

Tetracycline.

Yes, they can

Medicines such as antibiotics, pain killers, and antiseptics used to sustain health also have detrimental, environmental side effects. A large portion of consumed drugs has inevitably affected our environment for a long period of time. It is now possible to end the accumulation of micropollutants through effective removal of active pharmaceutical ingredients (API).

In parallel worldwide private and public initiatives are taking action to encourage the current development in neutralizing harmful micropollutant emissions. Mellifiq is a global engineering company, specializing in implementing the most efficient treatment methods for API removal for municipal wastewater treatment plants and the pharmaceutical industry.

We present our technology, engineering expertise, and consulting services required in order to deliver the world’s most cost-effective and energy-efficient solution. Only a fraction of active pharmaceutical ingredients (API) can be removed with traditional technologies, leading to harmful effects on flora, fauna and ultimately human beings.

Did you know

In Sweden, we use more than 1,000 different active substances in about 7,600 different drugs. In addition, there are about the same number of excipients and many kinds of packaging materials. Most new drugs that are approved for sale in Sweden are new makes of already known and used substances. New substances, however, count every year.

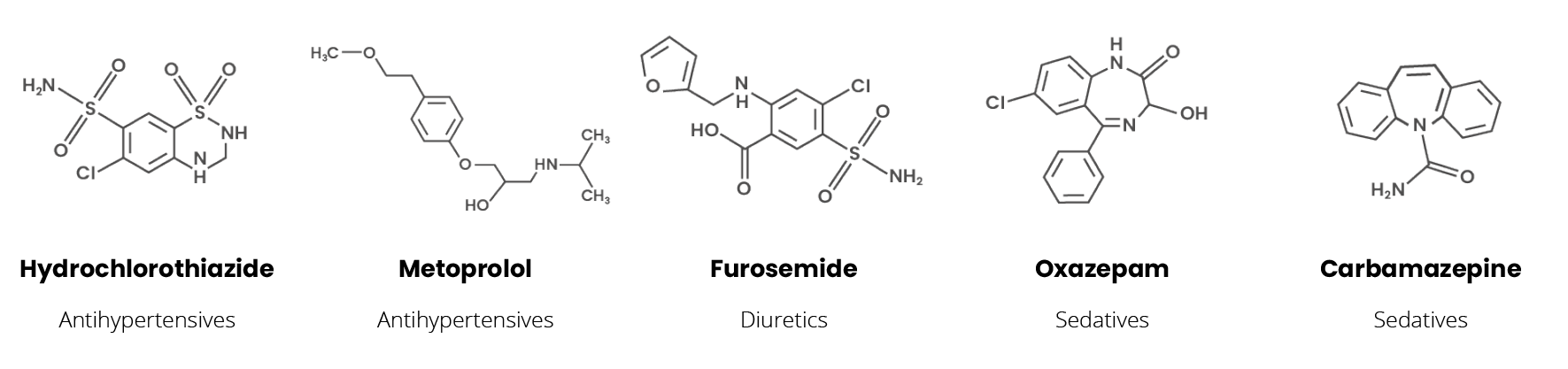

Commonly found pharmaceutical residues

Overview of commonly found active micropollutants in wastewater effluents:

Paracetamol

Paracetamol (N-acetyl-4-aminophenol) is a group of medicines (e.g. Alvedon) found in mild analgesics or non-steroidal antiinflammatory drugs that are sold in large quantities. They are commonly used for reduction of pain and fever symptoms. The projected annual world production of paracetamol is about 145,000 tons. The paracetamol molecule consists of a benzene ring core, substituted by one hydroxyl group and the nitrogen atom of an acetamide. More info about the paracetamol degradation with ozone treatment can be found below.

Codeine

Codeine (3-Methylmorphine) is a narcotic medication (e.g. Oramorph) used to treat moderate pain and cough. It consists of an aromatic ring and a quaternary carbon atom linked to a tertiary amine group by two other carbon atoms. This chemical characteristic is also known as the morphine rule. The molecule consists of a total of five rings, out of which three are in the same plane.

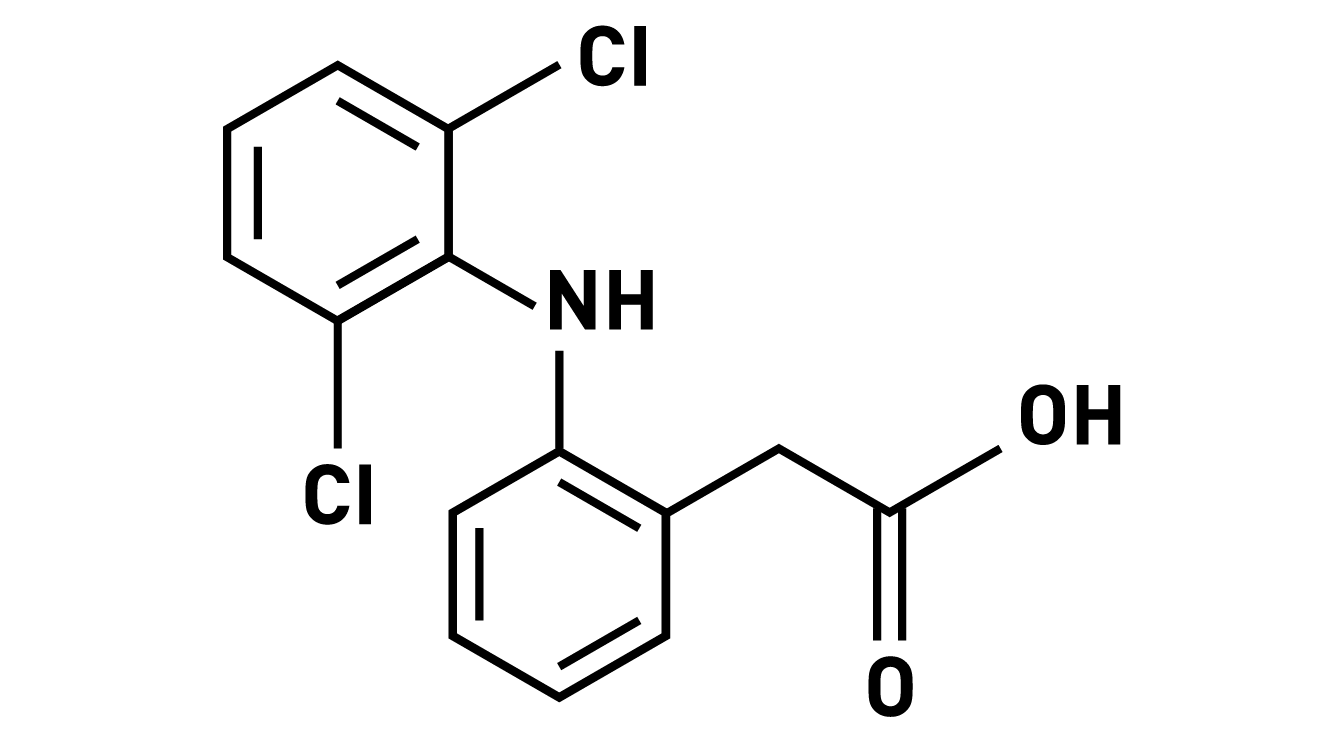

Diclofenac

Diclofenac 2-(2, 6-dichloranillino) phenylacetic acid is a non-steroidal anti-inflammatory drug (i.e. Voltaren) that is easily available in medical outlets and hundreds of tons are sold worldwide every year. It consists of two adjacent aromatic rings, with one ring bearing a carboxylate and the other one, a phenyl ring, binds perpendicular to the top of aromatic ring with two ortho-chloro groups.

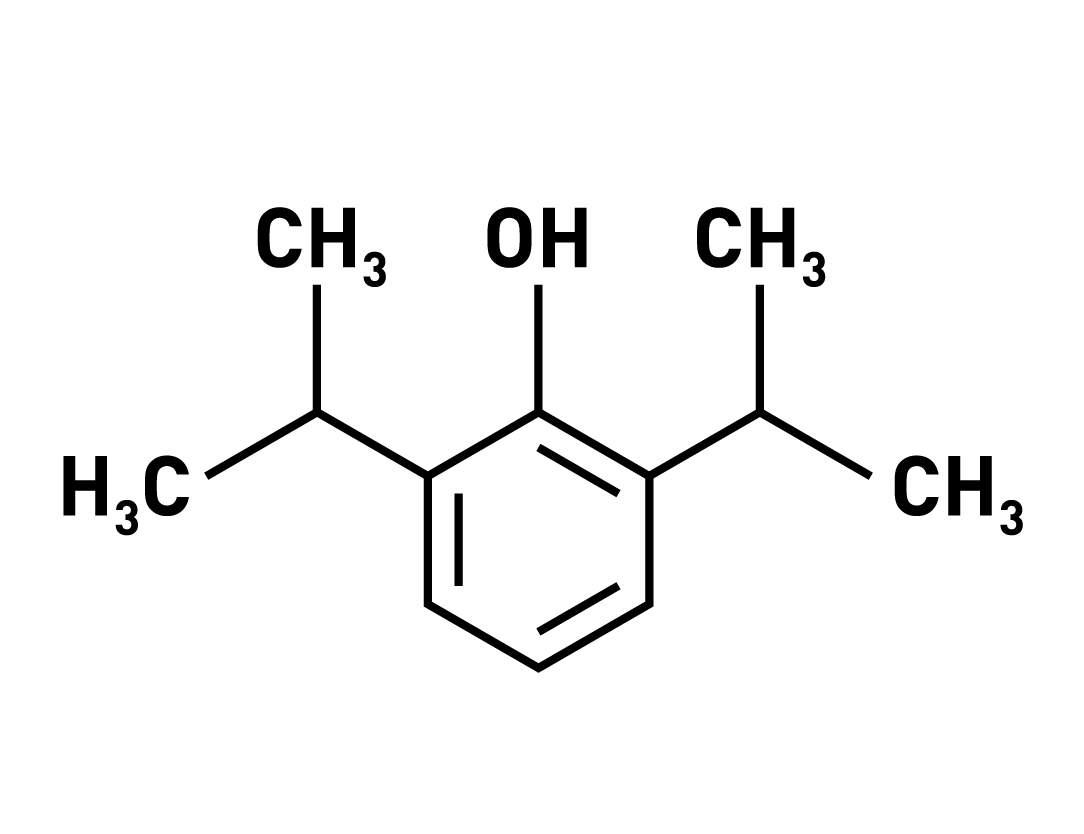

Propofol

Propofol (2,6-Bis (1-methylethyl) phenol) is a stable molecule and an intravenous anesthetic agent used in maintenance of general anesthesia (e.g. Propoven). Propofol consists of a benzene ring and an isopropyl group. Propofol, like the other compounds mentioned above, is effectively degraded to below detection levels with ozone treatment. Propofol in particular has shown a first order reaction in type in a typical wastewater effluent from pharmaceutical industry.

Major sources of pharmaceutical residues

Hospitals

Pharmaceuticals can be found in natural waters as a result of flushing down leftover products at private homes but a large source is hospitals. Therefore ozone technology should be considered to enhance the performance of hospital wastewater treatment plants or as tertiary at municipal wastewater treatment works. It has been found that hospitals contribute to around 20% of the pharmaceutical load in sewer streams as reported by EU The PILLS Project.

Pharmaceutical industry

In the pharmaceutical industry, measures can be taken to eliminate pharmaceutical residues from the production process wastewater. The industry is a major source of pharmaceutical micropollutants which can be identified in municipal wastewater treatment plants. There is an increasing demand on manufacturers to eliminate pharmaceutical residues prior to emitting the process wastewater.

Methods to treat pharmaceutical residues

A number of techniques exist today, which may act as a complement to the secondary, biological treatment found in wastewater treatment plants.

Powdered Activated Carbon (PAC)

PAC acts as an effective micropollutant filter and can be used as a tertiary treatment step in wastewater treatment. It may remove up to 86% of pharmaceutical residues by adsorption and provides not only transformation of target substances but removal.

UV

UV is a cost-efficient way of treating clear wastewater, but has limited ability to break down pharmaceutical residues. It has been reported by Kovalova, et al. (2013) that 33% of micropollutants can be removed on average by applying this technology. UV may effectively remove ICM using high dosages, such as Diatrizoate and Iopamidol.

Ozone treatment

Ozone is a potent oxidizing agent which effectively breaks up the chemical bonds in complex molecules, which makes it an efficient method to remove pharmaceuticals in the wastewater. Ozone can also be used in advanced oxidation processes (AOP) to boost radical formation in addition to the natural formation during ozone reactions. It has been shown that up to 100% of pharmaceutical micropollutants can be removed using ozone. Commonly applied range is 0.3 to 1.2 g O3/g DOC (dissolved organic carbon) according to Barasel, et al. (2015).

Mellifiq has over 20 years experience of advanced oxidation processes and has conducted a large number of projects with 100% removal of pharmaceutical residues in the process water. The figure below displays actual break-down of a common pharmaceutical residue by ozone and ozone-AOP processes.

Treatment of pharmaceutical residues with ozone

About 100,000 diverse chemicals are registered in the Europe Union (EU). Out of these 100,000, about 30,000 are distributed in large quantities, where each one is distributed in quantities of about one ton per year or more for human health consumption. During production, disposal and after regular use, a substantial portion of these active substances (micropollutants) are inevitably entering the aquatic environment.

Pharmaceuticals are one of the most important classes of emerging contaminants in water treatment processes and have a direct impact on human health and the ecosystem. The sources of pharmaceuticals include livestock residues, hospital discharge, aquaculture and release from domestic and industrial wastewater effluents. Among them, treatment of wastewaters has become increasingly difficult due to several reasons, including:

- Discharged wastewater contains clusters of micropollutants (i.e. pharmaceutical active substance) that are resistant to biological wastewater treatment processes. This is due to the complex molecular structures of these compounds.

- Stringent regulations on effluent discharge limitsUntreated, pharmaceutical residues promote the emerging problems of antibiotic resistant bacterial strains.

Methods for treating pharmaceutical residues at manufacturer: benefits and challenges.

| Method | Benefits | Challenge |

|---|---|---|

| Incineration of process wastewater containing micropollutants | Treatment conducted on-site. No costs for transportation to and handling of third party. | Treatment conducted on-site. No costs for transportation to and handling of third party. |

| Destruction off-site. Transportation to a third-party recycling company. | Scheduled shipping and destruction handled by a third party. | Very high costs. Fees and costs relating to third-party handling. Requires buffer tank and handling of process water between collection of process water. |

| Ozone treatment of pharmaceutical residues | Treatment conducted on-site and on-demand. System footprint less than 4 sqm. Less handling of untreated process water. Very low operational cost. Payback time 0.5 -2 years, depending on flow and substance. Safe use. | New mechanical installation but at a low footprint. |

Ozone technology provides a cost-effective alternative to traditional destruction by incineration. Mellifiq employs the Ozonetech RENA CIP or RENA AOP engineered systems to break down these micropollutants which will save large amounts of the operational costs associated with destruction. The figure below displays estimations for operational costs, comparing the heating and evaporating of process water and ozone treatment for micropollutants. Note that any handling costs for off-site incineration destruction are not included in the comparison below.