Treating exhaust air in commercial kitchens

Safe, clean and efficient exhaust treatment with ozone

Why ozone treatment for kitchen exhaust?

Air discharged from commercial kitchens and restaurants, especially kitchens where deep fryers are used frequently, contain large amounts of grease in the cooking fumes. The fumes contain heat energy, odor molecules, soot and grease particles. The heat causes the grease to take either liquid form, gaseous form or in form of aerosols.

The kitchen ventilation should provide a good working environment by venting the cooking fumes, heat and odors from the kitchen while simultaneously supplying fresh air. Ideally, the ventilation system should ensure that

the rest of the property and surroundings are not negatively affected by the kitchen operations.

The illustration below shows an exhaust ventilation in a commercial kitchen without ozone treatment.

The large grease particles are separated and entrapped by an air filter in the kitchen hood. The air then continues through the ventilation duct with odors and smaller airborne grease particles. Without efficient and continuous air purification, these will follow the exhaust air flow through the entire duct and adhere to the duct walls, the fan, the heat exchanger and the pre-filter of the heat exchanger. A small part remains airborne and passes into the environment like odor.

Over time, fat deposits are generated in the kitchen ventilation. Grease is a very energy-rich fuel and constitutes, therefore, a large and real fire hazard if ignited. Learn more about how to increase fire safety.

Odors emitted from the ventilation exhausts to the surroundings can cause complaints from residents and businesses. These complaints may lead to authorities forcing the person in charge to take immediate action. Learn more about how to reduce odor problems.

Restaurants and kitchens with equipment such as deep fryers, grills, woks or griddles need a reliable, high capacity purification system that continuously purifies the air from grease.

Purifying the exhaust air and kitchen duct enables:

- Optimized heat recovery

- Increased fire safety

- Less odor problems

- Possibility to utilize cheaper ventilation material

- Lower operational costs

- Reduced environmental impact

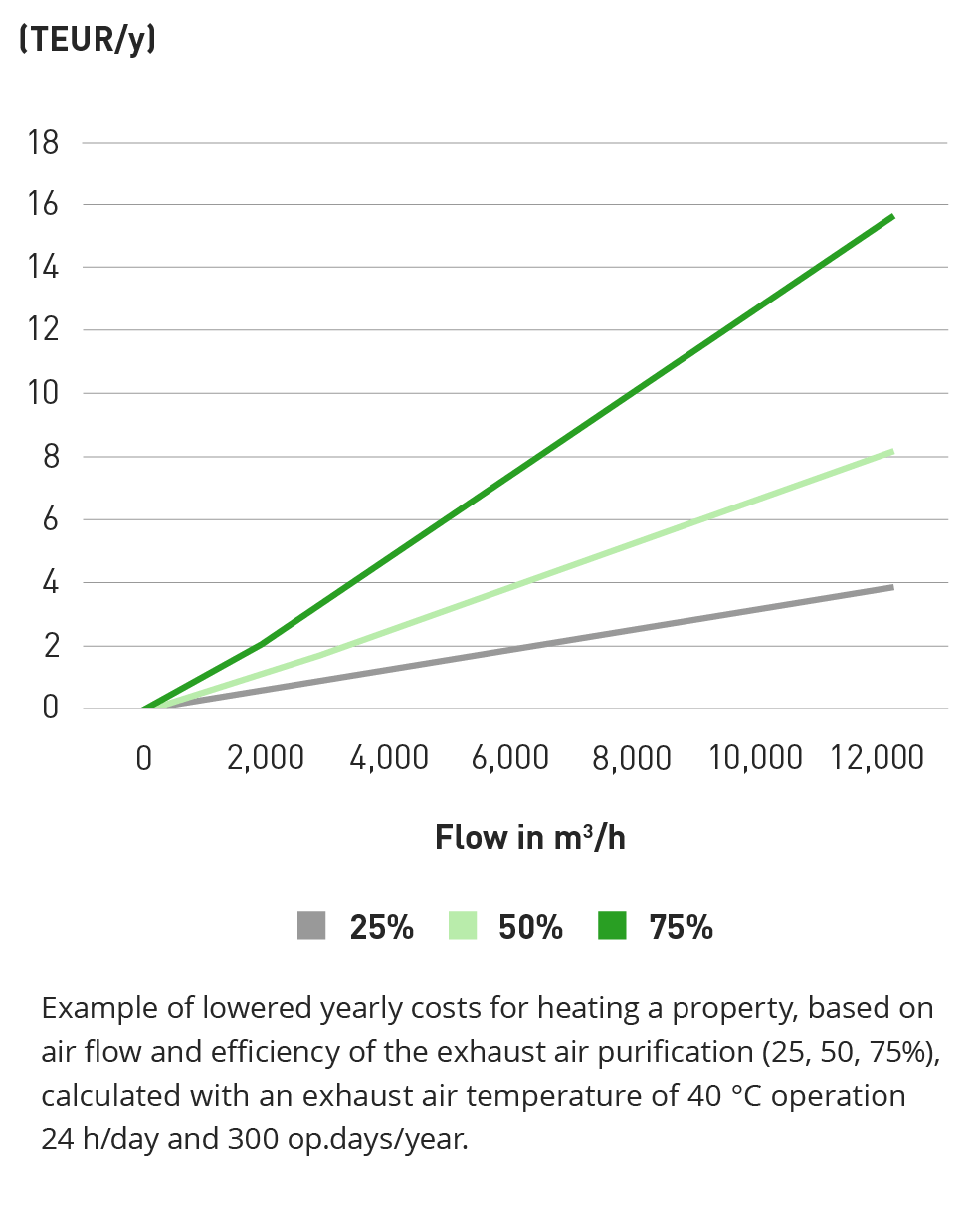

Hot purified air is a valuable asset that directly affects the energy consumption of the property. As an example, a restaurant with an exhaust air flow of 5,000 m3/h (i.e. 1380 l/s) loses energy approximately worth 13,500 EUR per year. Utilizing efficient purification of the exhaust air, up to 82% of energy can be recycled and large sums saved.

See the diagram on the right.

System design optimization

Ventilation in a commercial kitchen

A well-designed ventilation system in a commercial kitchen is a prerequisite in achieving a good working environment. Cooking fumes, heat and odors emitted from the kitchen must be removed while fresh air needs to be supplied. The ventilation system should also ensure that the property and its surroundings don’t suffer from any unpleasant odors during operation of the kitchens.

Optimal treatment of exhaust air in three steps

Step 1 – Particulate filter

A well-functioning particulate filter placed inside the kitchen hood is the first important step to achieve proper treatment of exhaust air. The filter must be able to trap larger grease particles from the exhaust air before it moves on to the inlet duct. Select the particulate filter with care.

Step 2 – Ozone system

The exhaust air that has passed the particulate filter needs to be treated further in the next step with a treatment solution that gets rid of the large amount of small grease particles and odors that remain in the air stream.

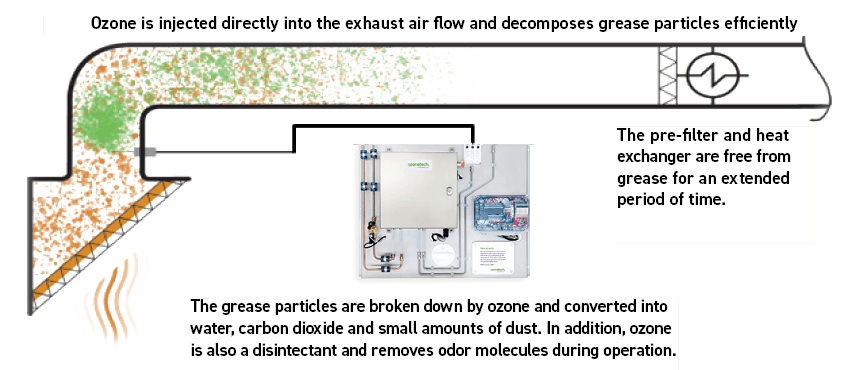

Ozonetech offers two treatment solutions, both of which produce ozone that breaks down the smaller fat particles into carbon dioxide, water and a little dust that is then transported through the ventilation system without adhering to the inner walls of the duct. Ozone also removes the majority of all odor substances in the exhaust air. Ozone is produced on site and injected into the exhaust air flow.

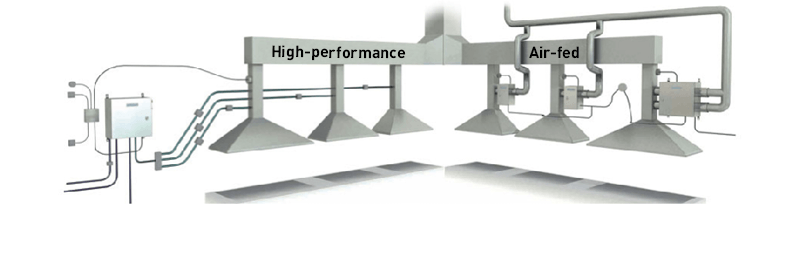

Two types of ozone systems

Air-fed ozone generator

Generates ozone from oxygen in the ambient air. Mounted directly into the ventilation above the hood. Best suited for smaller kitchens with an air flow below 2,500 m3/h (i.e. 700 l/s).

High-performance ozone generator

Fed with dry, pure oxygen and is mounted on the wall in a nearby area e.g. a corridor, passage or cleaning closet. Best suited for average or large kitchens, food courts etc. with an air flow above 2,500 m3/h (i.e. 700 l/s).

Step 3 – Final air treatment

In order to be able to release the exhaust air into demarcated or odor-sensitive environments, it is necessary to remove the remaining odors from the exhaust air. Read more about Nodora – our newly developed solution for treatment of all types of odor problems.

Tip

A number of parameters shall be taken into account when faced with the choice of treatment systems for commercial kitchen ventilation and exhaust ducts.

Ask others that have already installed treatment systems:

- What is the system’s total annual operating cost?

- How often does the system require maintenance or oversight? By the kitchen staff? By authorized technicians? By duct cleaners?

- Does the system require regular replenishment of some sort? Is it mandatory to stock up on chemicals? What are the by-products? Does the treatment involve frequent replacements of costly consumables?

Ozone and ozone generators have been used since the middle of the 20th century to treat both air and water worldwide. Purifying kitchen exhaust air with ozone became an established technique in the early 2000s. Using ozone and oxidation technology you can effectively break down fats, odors and other unwanted substances.

Our solutions purify the kitchen exhaust both efficiently and continuously, year after year. The systems are based on the principle of generating high-quality ozone on site that is injected directly into the exhaust airflow. However, in order to achieve an efficient ozone-based solution, there are several parameters to keep in mind, such as:

- The air flow

- Reaction time*

- Length and cross-section of the ventilation ducts

- Amount of grease

- Amount of ozone needed

- Location of ozone injection

- How the ozone is injected

- External factors that may disrupt the treatment compounds, a reaction time of at least two seconds is required. The length of the duct should, therefore, be dimensioned to ensure that at least two seconds is achieved between the injection point and the point of discharge or dilution.

*To achieve decomposition of grease and odor compounds, a reaction time of at least two seconds is required. The length of the duct should, therefore, be dimensioned to ensure that at least two seconds is achieved between the injection point and the point of discharge or dilution.

Ozone treatment technologies

Ozone generators

The principle for treatment of kitchen exhaust air with ozone is that ozone is generated in a generator located outside the ventilation duct. Ozone is then injected into the airflow, where it reacts on grease particles and pollutants continuously across the whole length of the ventilation. Ozone generators are normally divided into two categories:

- Air-fed ozone generators

- High-performance ozone generators

Both techniques have their own application areas and advantages, which makes them suitable for different requirements and airflows. Read more about how to select the right product for the right application. A general benefit with ozone-based systems is that they do not need to be replenished with any type of chemicals. All that is needed are small amounts of air and electricity. Another benefit is that no parts of the treatment equipment need to be immersed into the greasy exhaust air (c.f. UV-lamps), which significantly lowers the amount of maintenance and consumables needed. Ozone, O3, is a powerful oxidant but also an unstable gas, which means that residual ozone that hasn’t reacted, breaks down by itself quickly and returns to normal oxygen, O2. It is a great advantage compared to the use of bacteria or other chemicals.

Air-fed ozone generators

Air-fed ozone generators began to be used in the early 2000s. Ozone is formed when the oxygen in the air (21%) gets in contact with an electric field (corona discharge). These generators should be fed with clean supply air from the general ventilation.

Air-fed ozone generators have lower cleaning capacity and therefore fit for street-food establishments, cafes and smaller restaurants with low airflows, below 700 l/s, with only one/a few kitchen hoods and moderate grease loads. Ozonetech’s air-fed FTX system is an economic choice in these applications.

We recommend that air-fed ozone generators are only used in applications that are in accordance with EU standard EN 16282-8.

Usually, each hood requires its own dedicated air-fed ozone generator. The ducting between the ozone generator and the ventilation channel must consist of an ozone resistant material, e.g. SS316L.

Advantages of Ozonetech’s ftx-series

- Simple handling – connection to electricity and air duct is all that is required

- Suitable for smaller flows – suitable for kitchen hoods in smaller restaurants with moderate grease loads

- Stainless steel

- IP64 class

- Compact design

- Silent operation – below 50 dBA for a healthy work enivronment with low noise levels

- Maintenance – no polishing or cleaning of the ozone element required. The ozone module is readily replaced at low cost if necessary

- Adjustable ozone production (4-20 mA)

- Low investment costs

High performance ozone generators

Restaurants and commercial kitchens with a deep fryer, grill, wok or griddle demand a highly functional air cleaning system. The kitchen should be fireproof as well as efficient from both a purification and cost perspective. A high purification capacity is required to get rid of grease and cooking odors in the exhaust air. Our experience is that large airflows with high grease loads require a high-performance RENA-system to achieve proper purification. These products have previously only been available for the industrial market, but since 2015, we have made it possible to utilize their unique advantages for all types of restaurants and commercial kitchens.

A central high-performance ozone system distributes ozone by the means of ozone-resistant hoses or pipes to several injection points. This makes it possible to clean the entire duct length as the ozone injection can be done close to the kitchen hood.

With a cleaning capacity that supports up to 12,000 l/s and several kitchen hoods, the system becomes cost effective. The RENA systems have a very high performance because of high quality components and efficient liquid cooling.

Benefits with RENA Kitchen Solutions

- High purification capacity – one ozone generator can handle up to 12,000 l/s (approx. 43,000 m3/h)

- Central ozone system – one ozone generator enables efficient treatment of several hoods and ducts

- Flexible installation – the equipment may be placed elsewhere than in the kitchen

- Low LCC – RENA Kitchen Solutions are less expensive with lower lifecycle costs (LCC) compared to equivalent installation with several air-fed ozone generators

- High reliability – Due to liquid cooling medium, approved design and high requirements from industrial applications

- Easily placed and positioned

- Ozone distribution through hose/pipe – easy and flexible to reach one or several injection points near the duct

- No air supply– high-performance RENA Kitchen consumes minimal amounts of air

- SFP-value unchanged (Specific Fan Power) – no pressure drop or airflow balance is affected in the ventilation system

- Adjustable ozone production – manual or 4-20 mA-control

- Silent operation – below 50 dBA which is recommended for a healthy working environment

How to succed?

Our in-house developed RENA-systems are tailored and manufactured in our own facilities in Sweden. Over 25 years of experience has allowed us to map the most common mistakes made during design and installation of ozone systems. Consequently, we have compiled 20 key factors that we believe should be taken into account in order to succeed with your ozone installation.

The prerequisite for a successful and efficient air treatment is that the whole “kitchen exhaust air treatment“-chain is properly adapted to the local conditions.

Read more in our brochure The Right Product for the Right Application for more information on high-performance ozone generators (RENA Kitchen) and air-fed air-cooled ozone generators (FTX).

Do you have the right product for the right application?

| 1. Purpose of the treatment | Grease reduction and fire safety, energy recovery or odor reduction? |

| 2. Type of cooking | What is the grease load in the exhaust air? What are the sources of grease and cooking odors? |

| 3. Air flow | How high is the air flow that needs to be treated? |

| 4. Number of hoods/kitchens | Do you need to treat several hoods/kitchen exhausts? Are there multiple injection points? |

| 5. Exhasut air | Where is the discharge point? On the roof, from the façade or into a courtyard/pedestrian street? |

| 6. Ducting | What is the length and dimensions of the duct? Is optimal reaction distance reached? |

| 7. Purification capacity | Is the right amount of ozone used for the air flow and the type of cook-ing? |

| 8. Ventilation balance | Is the ozone system allowed to affect the ventilation balance of the ventilation system in the building? |

| 9. Injection point | Where is the injection point and does it treat the most flammable part of the duct? |

| 10. Energy recovery | Should heat be recycled? What type of heat exchanger is used? |

| 11. SFP-value | Does the intended ozone system affect the SFP value? |

| 12. Filter | Is an additional filter required? |

| 13. References | How does the solution work in similar installations? |

| 14. Choice of material | Which materials are used in the generator? Stainless steel or ozone resistant stainless steel? |

| 15. Product specifications | Does the product have a calibration certificate? |

| 16. Operating costs | What are the actual operating costs? |

| 17. Maintenance | What type of maintenance is required? How often? What are the costs? |

| 18. Noise level | How much noise is generated by the product? |

| 19. Experience | How much experience does the supplier have? What do other clients think of them? |

Solutions & systems for kitchen exhaust

Restaurants and commercial kitchens equipped with deep fryers, griddles, woks or frying tables require air treatment systems with high efficiency and reliability.

The kitchen should be fireproof and efficient in terms of grease/odor removal and costs.

In order to properly remove grease and odors in the kitchen exhaust, high treatment capacity is required. In our experience the RENA Kitchen Solutions, our high-performance ozone system, is the right solution for the task. These products have previously only been available for the industrial market, but since 2015, we have made it possible to utilize their unique advantages for all types of restaurants and commercial kitchens.

In cases with extra high requirements; for example, where potential odor problems may limit the scope of a kitchen design project or revoke the permission to run a commercial kitchen, our RENA-technology can be combined with our efficient odor removal solution Nodora.

However, in real estates, odors may originate from other areas aside from the kitchen. Our ozone generators in the ACT-series are a perfect choice for removing odors in garbage rooms and grease trap.

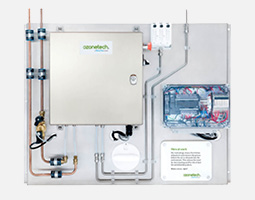

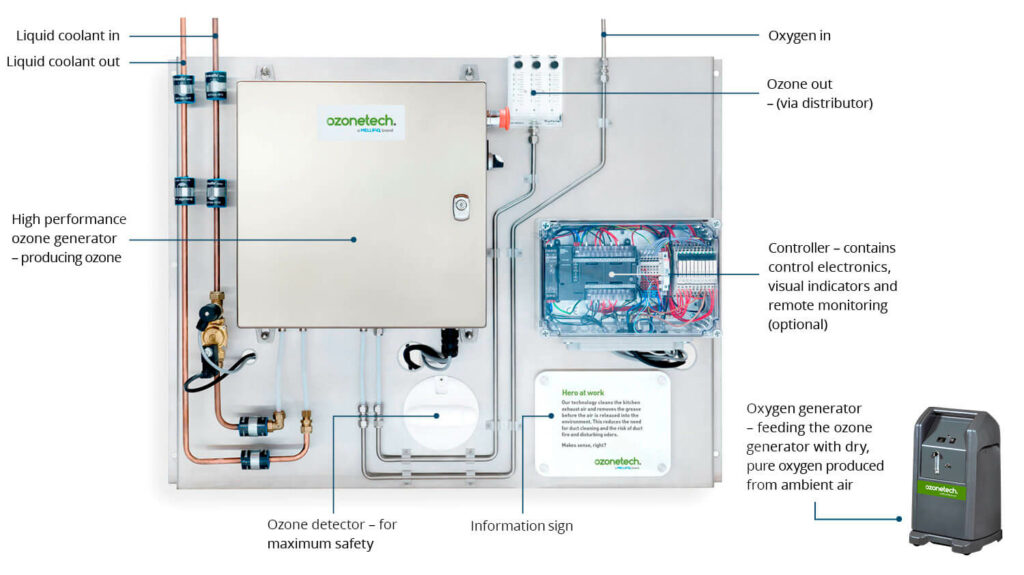

RENA Kitchen Solutions

RENA is our most powerful system solution. It is developed for commercial kitchens and restaurants with one or several hoods. Components are mounted on a stainless steel plate placed adjacent to the kitchen or further away in another room.

The level of safety is high. Ozone production shuts down if something out of the ordinary occurs. The system is remotely monitored and we receive alarms directly to our Service Center who can fix and restart the system.

Ozone treatment brings many benefits. When the grease deposits in the kitchen duct are reduced, the fire safety increases. With an increased fire safety, less expensive materials than stainless steel may be used in the ducts. The odor decreases considerably in the air discharged into the environment. When grease in the exhaust air is reduced, the energy in the air can be recovered.

The cost for heating premises is reduced by up to 80% when the energy is recovered.

RENA Kitchen Solutions has a very low operating cost and the maintenance requirements are minimal. The raw material (ambient air) is free. Nothing needs to be purchased, transported or managed.

You avoid moving parts, mechanical cleaning, fillings, waste and residues.

Ozone purification is an efficient and reliable method to treat exhaust ducts in commercial kitchens and restaurants. This has been discovered by thousands of property owners, municipalities, commercial kitchens and restaurants worldwide.

Technical specifications

Our RENA solutions are fed with dry, pure oxygen and are cooled with liquid. It is a very efficient and reliable technology to produce ozone. Day after day, year after year, purification capacity is constant. Ozone production is steplessly adjustable and easy to change if required.

A single RENA system is capable of producing enough ozone for multiple hoods, large airflows and high grease loads.

RENA is available in seven models for different air flows. The ozone system components are mounted on a stainless steel plate simplifying installation.

Read more in our brochure for more information and find the right model for your establishment.

Ozone production

| Distribution | The amount of ozone can be distributed individually for each hood |

|---|---|

| Cooling technology | |

| Liquid-cooled | Tap water/closed-loop cooling system |

| Ozone system | |

| Size horizontal (W x H x D) | 970 x 750 x 265 mm |

| Size vertical (W x H x D) | 695 x 1100 x 265 mm |

| Noise level | less than 50 dBA |