Digester chamber ozonation

Energy efficient H2S treatment and enhanced methane upgrade

The presence of hydrogen sulfide (H2S) is an issue in many cases, especially in biogas plants. In this paragraph, we focus in particular on two-stage biogas plants, where the anaerobic digester is separated from the methane upgrading unit. In this case, high concentrations of H2S are formed already in the digester, where ozone can be injected to reduce this issue.

Since the digester is operating in anaerobic conditions i.e. absence of oxygen, ozone should be injected with care. The injection is done in the air pocket above the microbial reacting bed. In alternative, an additional tank for the ozonation can be added between the digester and the methane upgrade unit. This solution is safer for the anaerobic conditions but requires extra installation costs.

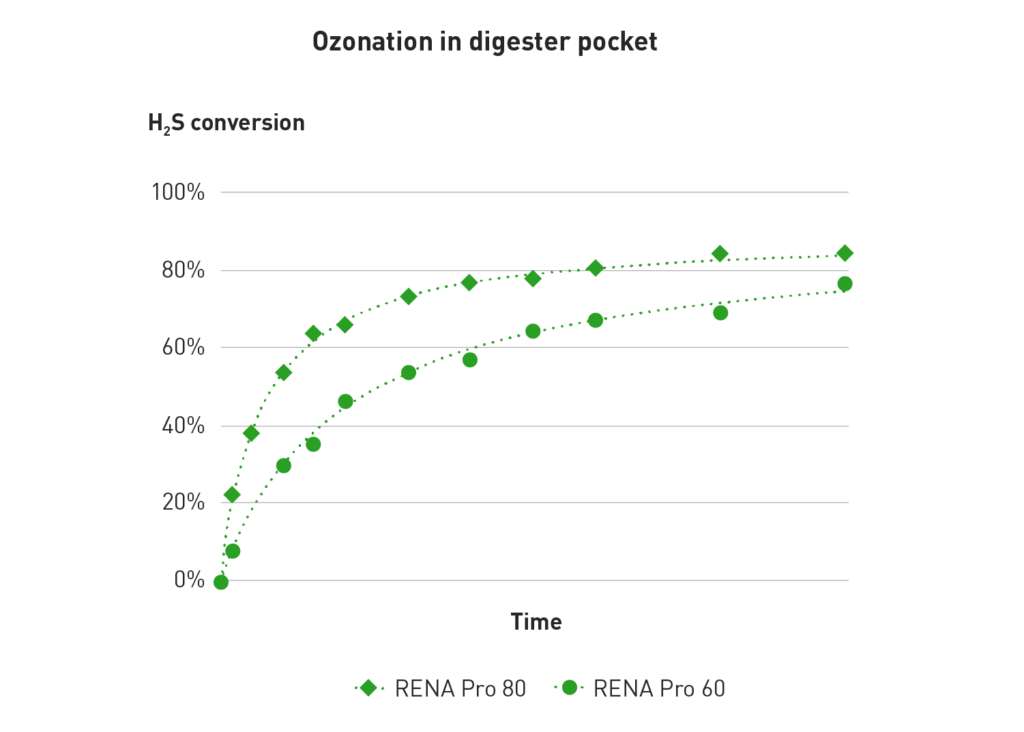

The air pocket above the reacting media offers quite a large volume for the ozone to react with the H2S. Therefore, the oxidation reaction with ozone is particularly effective. The H2S conversion for a reference case of ozonated digester is summarized in the figure below.

Figure 1 – H2S removal in biogas digester with two different RENA Pro solutions.

As shown, ozone successfully treat H2S with conversions above 80 %. This means that ozone is capable of reducing the H2S concentration from 500 – 1000 ppm to 75 – 150 ppm already before the methane upgrading stage. Based on the incoming conditions and requirements, we offer a range of tailor-made solutions, optimizing the H2S removal and minimizing the energy consumption. H2S is converted into SO2, greatly reducing the odor and corrosion problems, according to the reaction below.

Compared to other technologies, ozone offers several benefits for reducing H2S in digesters. For example, the use of iron chloride in the bio-bed has been the common practice for several years. However, this practice requires high operational costs, since the iron chloride is continuously consumed during the anaerobic digestion. In addition, there may be corrosion problems due to the high corrosion potential of iron chloride.

Compared to air or oxygen injection, ozonation is much more effective due to its high oxidation potential. When air is used, the presence of nitrogen significantly decrease the biogas grade, since it has a high concentration and it cannot be removed in the following steps of the process. The use of oxygen solves the problem of lowering the biogas grade; however, the performance is inferior compared to ozone. Since oxygen has a lower oxidation potential, the oxidation reaction happens slower compared to ozone. This means that an oxygen injection requires much larger volumes and reaction times. Therefore, the injection of oxygen cannot be applied in plants with limited space. On the contrary, ozone has a much faster reaction rate, resulting in an effective treatment even for small volumes.

Benefits of H2S ozonation in biogas digester

- High H2S removal (out concentration less than 100 ppm)

- High energy efficiency with low operational costs

- Flexible ozone dosage according to needs

- Plug and play system with low maintenance

- No corrosion or dangerous byproducts

- High biogas grade

RENA Pro for digester H2S ozonation

For the ozonation of H2S in the digesters, we recommend the use of our RENA Pro solution. This system offers superior performance due to the oxygen feed and the custom-made water cooling system. The oxygen is produced in-situ which the oxygen generator included in the solution. This unit produces oxygen from ambient air, filtering it and removing nitrogen and moisture.

The RENA Pro solution is completed with a PLC controller, an ozone sensor and a mounting skid.

Read more on our RENA Pro Solution or download our brochure.